Zellige tile technical sheet Composition, applicable standards and performed tests

-

Applicable standards & norms

Zellige tiles are handcrafted and not industrially manufactured, which makes every tile unique in its characteristics. Due to this non-standardized nature, there is no international norms (CE, ISO, DIN..) that could include and refer to Zellige tiles.

Nevertheless, we have carried out a series of standardized tests adapted to ceramic products on our Zellige tiles. Please find the results in the following section:Resistance to surface Abrasion*

ENAC laboratory, AICE-ITC, 2017.

Tests according to standard : UNE-EN ISO 10545-7:1999.

Results: Classification: CLASS 4. Abrasion stage at failure: > 12000 rev.Determination of resistance to Thermal Shock*

ENAC laboratory, AICE-ITC, 2017.

Tests according to standard UNE-EN ISO 10545-9:2013.

Results: Number of tiles tested 5; number of tiles with visible defects: 0.

Observed defects: No tested piece showed signs of thermal shock.Determination of chemical resistance*

ENAC laboratory, AICE-ITC, 2017.

Tests according to standard UNE-EN ISO 10545-13:1998.

Results: Ammonuim chloride 100g/l; no visible effect.

Hydrochloric acid 3%: no visible effect.

*Please note that due to the non-standard nature of the product, any test applies exclusively to the tiles tested. -

Composition and production

MOSAIC FACTORY Zellige is manufactured at our manufacturing facilities in Morocco, following traditional processes of craftsmanship.

Tiles are elaborated one by one from non-refined natural clay extracted in the region of Fez. This “white” clay is mixed and kneaded with water, moulded by hand, dried naturally and kiln-baked.

The glazing (vitreous compounds and mineral pigments) used at the MOSAIC FACTORY plant are of the highest quality and comply with EEC standards.Size and finish

Zellige tones vary subtly in depth, saturation, and reflection. Each tile has a unique irregular surface and color finish.

There also might be variations in thickness (+/- 1.5 mm) flatness and size.

We deliver tiles within a range of variation that we deem acceptable and according to the definition of Zellige – view showroom displays and images on our website for more information.Weight and packaging

Each standard square meter (11-12mm thickness) weighs 16/22 kg. The weight of the packaging, pallets and protection should be added for transport. Tiles are protected with foam dividers and packaged in boxes depending on shape. For example, 10x10 tiles are packed in 32x20,6x10 cm cardboard boxes containing 50 tiles and weighing 12 kilos.

-

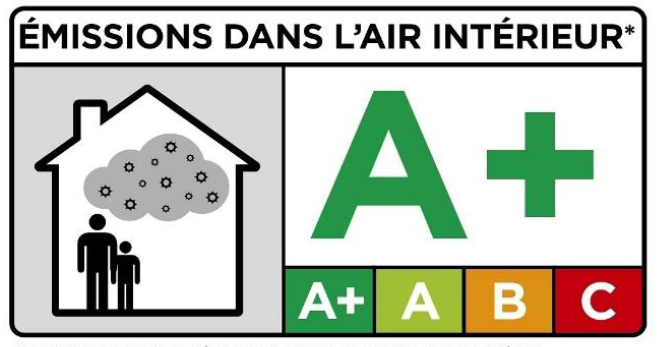

VOC Emission tests

Eurofins product testing, 2021

- French VOC regulation (DEVL 1133129ª):

- French CMR components (DEVP0908633A and DEVP0910046A): PASS - Italian CAM Edilizia (GU n.259): PASS - ABG/AgBB (Ausschuss zur gesundheitlichen Bewertung von Bauprodukten): PASS - Belgian Regulation (C-2014/24249): PASS - Indoor Air Comfort GOLD (Eurofins): PASS BREEAM International: Exemplary level LEED v4.1 BETA: PASS

STOCK

STOCK